Five Maintenance Signs for Telescopic Covers

How to Determine When Your Telescopic Covers Need Repairs?

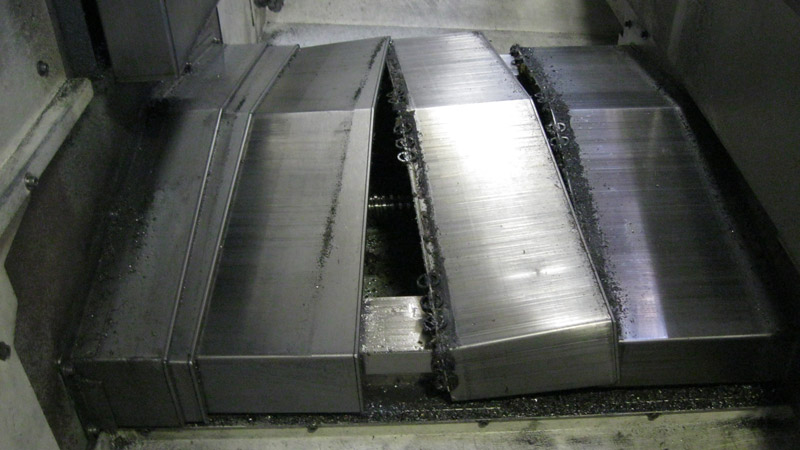

Telescopic covers are essential for protecting moving components from chips, dust, and coolant, ensuring smooth machine operation and prolonging equipment lifespan. With years of expertise in manufacturing high-quality telescopic covers, Tien Ding Industrial Co., Ltd. emphasizes the importance of regular maintenance to prevent wear and tear. Over time, these protective components can lose efficiency, potentially affecting machine performance.

To keep your equipment running at its best, it's crucial to identify early signs of wear and address them promptly. This article outlines five key indicators that your telescopic covers may need repairs, along with professional tips for maintenance.

1. Detached Components or Excessive Chip Accumulation

Scraper seals are vital for removing chips during machine operation. When they wear out or detach, chips can build up on the cover surface or within the machine, causing friction and inefficiency.

What to Watch For:

- Visible streaks or chip layers near the scraper seals.

- Chips gathering in hard-to-reach areas.

Solution:

Replace worn seals with durable materials like TPU to ensure effective chip removal. Prompt replacement minimizes risks to internal components.

2. Unusual Noises or Friction Sounds

Telescopic covers should operate smoothly and quietly. Abnormal sounds, such as grinding or squeaking, may indicate insufficient lubrication, misalignment, or damage to sliding components.

What to Watch For:

- High-pitched noises during cover movement.

- Resistance or friction when manually moving the covers.

Solution:

Lubricate sliding tracks regularly. Address misalignments and replace damaged parts to restore smooth operation.

3. Deformation or Cracks

Prolonged use or improper handling can lead to deformation or cracks in telescopic covers, compromising their ability to keep contaminants out and increasing friction with adjacent components.

What to Watch For:

- Warping, bending, or visible cracks.

- Gaps or misalignment between cover sections.

Solution:

Replace severely deformed or cracked covers. Ensure proper installation and alignment to avoid recurrence.

4. Restricted Movement or Jamming

Smooth extension and retraction are critical for telescopic covers. If they become stuck or fail to open and close completely, this could signal internal damage, misalignment, or chip buildup.

What to Watch For:

- Covers failing to extend or retract fully.

- Jerky or uneven movement.

Solution:

Clean sliding tracks thoroughly and remove any blockages. Inspect internal components for damage and replace as necessary.

5. Surface Rust or Corrosion

Metal covers exposed to humid environments or damaged coatings can develop rust, increasing resistance and compromising scraper seal functionality.

What to Watch For:

- Rust spots or discoloration on the metal surface.

- Scraper seals failing to function due to corrosion.

Solution:

Apply anti-rust treatments regularly. Replace corroded components with corrosion-resistant materials, such as stainless steel or covers with advanced coatings.

Additional Maintenance Tips

To maximize the lifespan of your telescopic covers, implement a proactive maintenance routine. Here are five practical tips:

1. Inspect Regularly

Schedule monthly inspections to check for wear, debris accumulation, and lubrication.

2. Use High-Quality Replacement Parts

Opt for durable materials when replacing seals or rails to ensure reliable performance.

3. Monitor Environmental Conditions

Keep factors like humidity and coolant exposure in check to minimize wear.

4. Upgrade When Needed

Consider enhanced covers with advanced seals or corrosion-resistant features for demanding conditions.

5. Train Operators

Educate your team on proper handling and maintenance to prevent accidental damage.

The Cost of Neglect: Why Maintenance Matters

Ignoring warning signs can lead to:

- Damage to internal machine components from debris or coolant infiltration.

- Reduced machining accuracy and increased downtime.

- Higher repair costs from avoidable failures.

Proactive maintenance protects your investment and ensures better productivity.

Conclusion: Prevention Saves Costs

Telescopic covers are vital for maintaining the performance and reliability of your machine tools. Addressing wear and operational issues early prevents costly downtime. Regular inspections, high-quality replacements, and consistent maintenance keep your equipment in peak condition.

Contact Us

For expert advice or professional repair services, contact Tien Ding Industrial Co., Ltd. We offer tailored solutions to ensure your telescopic covers provide optimal protection and performance.

Catagory

Recent News

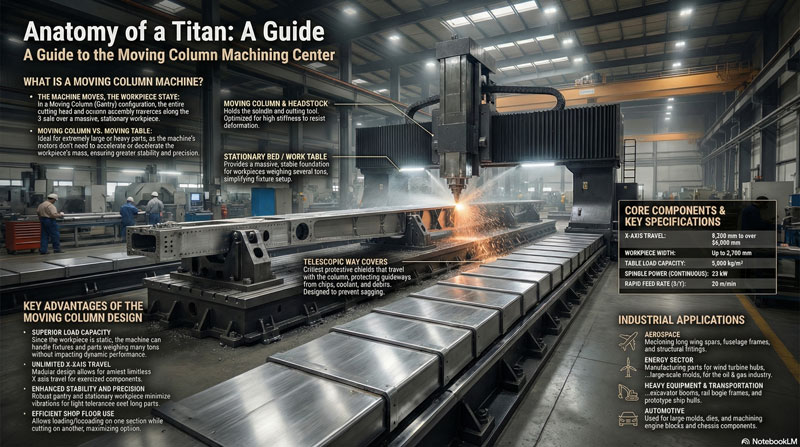

Key Design Considerations for Telescopic Covers in Moving Column Gantry Machining Centers

How ATC Mechanisms Influence Telescopic Cover Design in B-Axis Turning-Milling Machines