Advancing CNC Protection: Tien Ding’s Sustainable Telescopic Covers for the European Market

Innovative Lightweight Design | Machine Tool Protection | Enhancing Performance & Sustainability

A New Era for CNC Machine Protection in Europe

As Europe's CNC and machine tool industry advances, the focus on sustainability, energy efficiency, and operational cost reduction has never been greater. With stringent EU environmental regulations and growing commitments to ESG (Environmental, Social, and Governance) goals, manufacturers are actively seeking ways to enhance machine performance while minimizing their carbon footprint.

A crucial aspect of machine tool optimization is protection—specifically, the use of telescopic covers to shield moving components from contaminants, debris, and mechanical wear. Traditional telescopic covers, often made from thick, heavy materials, provide robust protection but come with challenges such as increased energy consumption, excess weight, and higher operating costs.

To address these challenges, the demand for lightweight, durable, and sustainable telescopic covers is rising. European manufacturers now seek solutions that not only enhance machine efficiency but also align with their long-term sustainability goals.

Why Lightweight Telescopic Covers Are the Future

The Limitations of Traditional Telescopic Covers

Historically, telescopic covers were built with thick iron plates to provide impact resistance and prevent external contamination. However, this conventional approach has several drawbacks:

- High Energy Consumption – Excess weight increases the load on machine components, resulting in higher power usage.

- Material Waste – Overuse of heavy metals leads to inefficient resource utilization, making sustainability compliance more difficult.

- Increased Maintenance & Costs – Heavier covers accelerate wear on motors and moving parts, requiring frequent servicing.

The Advantages of Lightweight Telescopic Covers

To overcome these issues, lightweight telescopic covers have emerged as the ideal solution for next-generation CNC machines. Their key benefits include:

- Lower Machine Load – Reduced weight translates to less strain on servo motors and drive systems, leading to improved efficiency.

- Optimized Sustainability – Less material use means lower production waste and reduced carbon footprint.

- Extended Component Lifespan – Decreased mechanical stress results in longer-lasting machine components.

- Cost-Effective Operations – Lower energy consumption and maintenance needs drive down total ownership costs.

By integrating lightweight materials with modern engineering techniques, manufacturers can achieve enhanced protection while ensuring greater sustainability and cost savings.

Tien Ding: Redefining CNC Protection for the European Market

As a leading provider of CNC machine protection solutions, Tien Ding Industrial Co., Ltd. has been at the forefront of telescopic cover innovation for over 35 years. Recognizing the need for lighter, stronger, and more efficient machine protection, we have developed a new generation of lightweight telescopic covers tailored for European manufacturers.

What Sets Tien Ding's Telescopic Covers Apart?

- Custom Solutions for High-Precision CNC Machines – Designed for 5-axis machining centers, lathes, milling machines, and multi-axis systems.

- Optimized Engineering – Lighter yet durable designs reduce energy consumption without compromising protection.

- Compliance with EU Standards – Fully aligned with European quality, safety, and sustainability requirements.

- Continuous Innovation – Dedicated R&D ensures our covers keep pace with evolving CNC technology.

We work closely with OEMs, machine tool builders, and distributors across Europe to deliver high-performance CNC protection systems that enhance productivity and extend machine lifespan.

Supporting Europe's Transition to Sustainable Manufacturing

As the European CNC industry moves toward smarter, greener manufacturing, companies must invest in future-ready solutions that align with their environmental and operational efficiency objectives.

Tien Ding Industrial Co., Ltd. is committed to being a strategic partner in this transition, providing telescopic covers that optimize performance while reducing waste and energy use.

By incorporating Tien Ding's lightweight CNC protection solutions, manufacturers can:

- Reduce Carbon Footprint – Lower energy consumption helps meet sustainability targets.

- Enhance Machine Longevity – Less stress on moving parts minimizes wear and extends service life.

- Lower Operating Costs – Increased efficiency translates to measurable cost savings over time.

As machine tool protection evolves, lightweight telescopic covers are becoming an essential investment for forward-thinking European manufacturers.

Explore Tien Ding's Advanced Solutions

We invite European machine tool experts to discover how Tien Ding's telescopic covers can enhance machine efficiency, sustainability, and durability.

For more information about our customized CNC protection solutions, contact Tien Ding Industrial Co., Ltd. today.

Catagory

Recent News

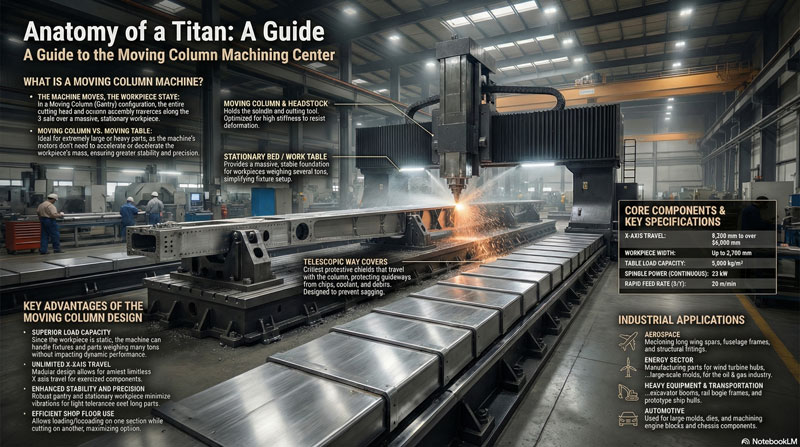

Key Design Considerations for Telescopic Covers in Moving Column Gantry Machining Centers

How ATC Mechanisms Influence Telescopic Cover Design in B-Axis Turning-Milling Machines