Key Design Considerations for Telescopic Covers in Moving Column Gantry Machining Centers

From Long-Stroke Constraints to Lightweight and Durable Engineering Solutions

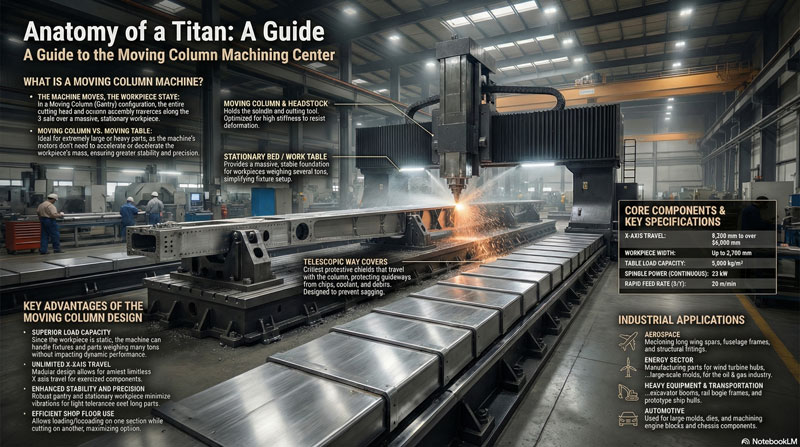

In applications involving large moving column gantry machining centers, telescopic covers are far more than basic protective components. While their primary role is to prevent chips and coolant from entering critical areas, their structural design directly affects machine dynamics, long-term stability, and overall maintenance cost.

Moving column machines are characterized by ultra-long X-axis travel, synchronized column movement, and heavy-load machining conditions. These features impose significantly higher engineering demands on telescopic covers compared to standard machining centers. As a result, cover design must address challenges related to stroke length, structural rigidity, rolling stability, and weight optimization from the very beginning.

Based on extensive real-world experience, Tien Ding Industrial Co., Ltd. has identified several critical—but often overlooked—design factors that determine the success and reliability of telescopic covers for moving column gantry machines.

1. Long Travel Is Inevitable — But Sheet Metal Size Limits Must Be Considered Early

One of the defining advantages of moving column gantry machines is their ability to achieve travel lengths extending to tens of meters. However, while stroke length is often the primary focus during machine planning, the physical limitations of sheet metal processing are frequently underestimated.

In practice, the maximum unfolded width of commonly available metal sheets is approximately 1500 mm. If this constraint is not considered during the early design phase, it can lead to:

-

An excessive number of cover segments

-

Increased structural complexity

-

Reduced rigidity or difficult assembly

For this reason, column width, cover segmentation strategy, and sheet metal unfolding dimensions must be evaluated as an integrated system during the initial design stage—not treated as issues to be corrected later.

2. For Long Panels, Structural Rigidity Matters More Than Simply Increasing Thickness

As individual telescopic cover segments become longer, bending stiffness becomes a critical factor influencing motion smoothness and reliability. Traditional design approaches often rely on increasing plate thickness to improve rigidity, but this method introduces new problems:

-

Increased cover weight

-

Higher load on column drive motors

-

Greater energy consumption and accelerated wear over time

Tien Ding adopts a different engineering approach: lightweight structural reinforcement. By optimizing reinforcement bends, cross-sectional geometry, and load distribution paths, overall rigidity can be significantly improved without excessive material thickness.

This design philosophy reduces unnecessary mass, lowers motor load, and enhances stability during high-speed reciprocating motion—particularly important for long-stroke applications.

3. Rolling and Guiding Contact Design Directly Determines Service Life

In telescopic cover systems, rollers and guiding elements are often treated as secondary components. In reality, they are key determinants of durability and long-term operational smoothness.

Tien Ding follows clear engineering principles in rolling system design:

-

Preference for line-contact rolling structures

-

Avoidance of point-contact ball bearing designs in long-stroke applications

Our roller systems typically incorporate self-lubricating bearings and precision-ground guide bars. Compared to point-contact bearings, line-contact designs offer:

-

More even load distribution

-

Reduced localized wear

-

Superior durability under long travel and high load conditions

This approach prioritizes long-term reliability over short-term friction reduction, ensuring stable operation throughout the service life of the telescopic cover.

4. Structural Design Ultimately Serves Overall Machine Performance

In moving column gantry machines, telescopic covers are not isolated components. They are directly linked to column dynamics, motor output, guideway accuracy, and machine responsiveness.

A well-engineered telescopic cover should:

-

Avoid adding unnecessary dynamic load

-

Maintain sealing integrity during high-speed motion

-

Reduce long-term maintenance and unplanned downtime risks

This system-level perspective is central to Tien Ding’s design philosophy for moving column telescopic covers.

Conclusion: Early Engineering Collaboration Is the Key to Eliminating Structural Risk

Moving column gantry machining centers are typically deployed for high-value, high-risk, and high-precision manufacturing tasks. In such environments, telescopic covers are not merely protective accessories—they are structural components that directly influence machine stability, motion accuracy, and long-term maintenance costs.

At Tien Ding Industrial Co., Ltd., we believe that reliable telescopic cover solutions are created through early-stage engineering collaboration, not post-installation corrections. By addressing travel length, structural rigidity, rolling contact design, and dynamic load behavior from the beginning, potential risks can be identified and resolved before they impact machine performance.

If you are planning a new moving column gantry machine, upgrading an existing platform, or facing challenges related to long-stroke protection and durability, contact Tien Ding Industrial Co., Ltd. Our engineering team is ready to support technical discussions at the design stage and provide customized telescopic cover solutions that help you achieve lighter structures, higher stability, and longer service life.

Frequently Asked Questions (FAQ)

Q1: Why are telescopic covers for moving column gantry machines more challenging than standard CNC machines?

A: Moving column gantry machines feature significantly longer travel distances, higher structural loads, and synchronized column motion. These factors place greater demands on telescopic cover rigidity, rolling system durability, and segmentation strategy compared to conventional machining centers.

Q2: Can increasing plate thickness alone solve rigidity issues in large telescopic covers?

A: Not effectively. While thicker plates increase stiffness, they also add weight, raise motor loads, and increase energy consumption. Optimized structural reinforcement geometry provides better rigidity without unnecessary mass.

Q3: Why does Tien Ding prefer line-contact rolling designs over ball bearings?

A: Line-contact designs distribute load more evenly and reduce localized stress, significantly improving durability in long-stroke, high-load applications where point-contact bearings are prone to premature wear.

Q4: When should telescopic cover design be considered during machine development?

A: Ideally during the early machine layout and motion planning stage. Late-stage integration often results in compromises that could have been avoided through early coordination.

Q5: Can Tien Ding support custom telescopic cover development for large or non-standard machines?

A: Yes. Tien Ding specializes in custom-engineered telescopic covers for large-format, long-travel, and high-load machine tools, providing design review, structural optimization, and feasibility evaluation.