Way Cover Maintenance: Prevent Wear, Detachment, and Chip Buildup

Introduction

Way covers are essential components in CNC machining, providing critical protection for precision machine tools by shielding them from cutting fluids, metal chips, and other contaminants. Without proper maintenance, issues such as scraper seal wear, detachment, and chip buildup can compromise machine performance and lead to costly repairs.

With decades of experience in designing high-quality protective solutions, Tien Ding Industrial Co., Ltd. understands these challenges well. In this article, Tien Ding shares practical insights and effective maintenance strategies to help you prevent common way cover issues, ensuring your machines operate efficiently and reliably for years to come.

Common Issues with Way Covers

Neglecting way cover maintenance can result in significant problems, such as chip accumulation, scraper seal wear, and impaired performance. The impact of these issues can be severe. The image below shows a way cover with accumulated chips and worn scraper seals, leading to inefficient operation and potential damage:

Way Cover Before Maintenance

Typical Issues Include:

- Scraper Seal Detachment: When scraper seals fall off, way covers can no longer effectively remove chips, leading to chip buildup that disrupts machine operations.

- Chip Buildup: Chips trapped on the cover surface can scratch and damage the way cover during high-speed movement.

- Inefficient Chip Removal: When chips accumulate for extended periods, they can impair machining accuracy and cause the way cover to jam or malfunction.

Professional Tips: Inspection and Diagnosis Essentials

Inspection Guidelines:

1. Check the Condition of Scraper Seals

- Inspect scraper seals for looseness, detachment, or significant wear.

- Look for signs of hardening, cracking, or deformation that could reduce sealing efficiency.

2. Check for Internal Chip Accumulation

- Open the way covers and visually inspect for accumulated chips or blockages in the chip removal channels.

- Pay attention to points where chips, coolant, and seals make contact for signs of degradation or abnormalities.

3. Test Chip Removal Functionality

- Manually move the way cover to observe if chip removal is smooth, without jamming or unusual friction noises.

Effective Solutions: Repair and Prevention Strategies

Maintenance and Repair Solutions:

1. Replace Worn Scraper Seals

- Remove damaged scraper seals and install new ones, ensuring they fit snugly against the way cover surface to prevent chip buildup.

- Use high-durability materials such as TPU (Thermoplastic Polyurethane) for improved impact and wear resistance.

2. Clean Internally Accumulated Chips

- Use brushes and vacuum systems to thoroughly clean chips and debris from the way cover tracks and chip removal channels.

- Check the lubrication status of the tracks and reapply lubricant if necessary.

3. Reinstall and Calibrate

- Properly reinstall the scraper seals and calibrate the way cover’s position to ensure smooth chip removal.

- Conduct test runs to confirm there are no unusual noises or movement issues.

4. Daily Maintenance Routine

- Perform regular inspections of the way covers, particularly after high-precision machining operations.

- Schedule monthly chip cleaning and seal condition checks to minimize risks.

Proper maintenance of way covers, including replacing damaged scraper seals and thoroughly cleaning internal chips, is essential to restore functionality. After performing these steps, way covers can efficiently protect machine tools once again. The following image demonstrates a cleaned and fully functional way cover.

Way Cover After Maintenance

Additional Issues to Consider

1. Coolant Contamination

Coolant can seep into the way covers, causing seals to deteriorate faster. Using coolant-resistant scraper seals can help mitigate this issue.

2. Wear from High-Speed Operation

High-speed CNC machines can accelerate the wear of way covers. Regularly inspecting for signs of stress, cracks, or deformations can help catch problems early.

3. Impact of Improper Installation

Poorly installed way covers or seals can lead to inefficient chip removal and premature wear. Always ensure proper installation and alignment during maintenance.

Conclusion

Proactive maintenance of way covers is essential for ensuring the longevity and efficiency of CNC machines. Addressing issues like scraper seal wear, detachment, and chip buildup early can help prevent serious damage and costly downtime. Regular inspections, timely repairs, and proper cleaning are key to keeping your equipment in peak condition.

For expert advice or comprehensive maintenance services, Tien Ding Industrial Co., Ltd. is ready to support you with reliable solutions tailored to your needs. Trust Tien Ding to help you maintain smooth and efficient operations. Contact us today to learn how our expertise can keep your machine tools performing at their best.

TEL:+886-4-25283698

Email:Sales@tdcover.com

Catagory

Recent News

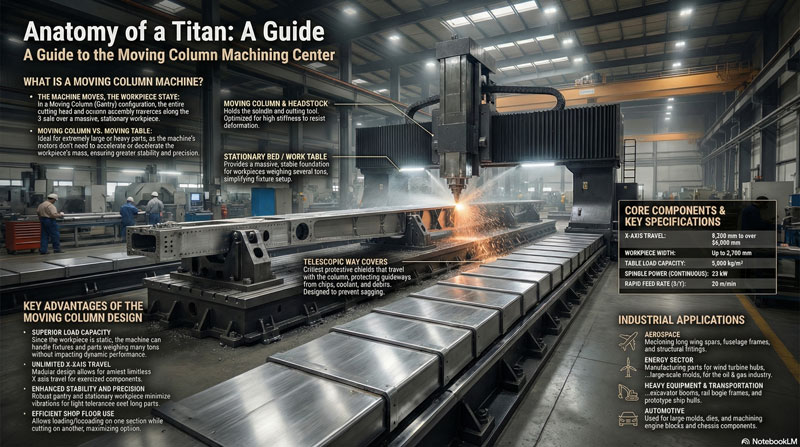

Key Design Considerations for Telescopic Covers in Moving Column Gantry Machining Centers

How ATC Mechanisms Influence Telescopic Cover Design in B-Axis Turning-Milling Machines