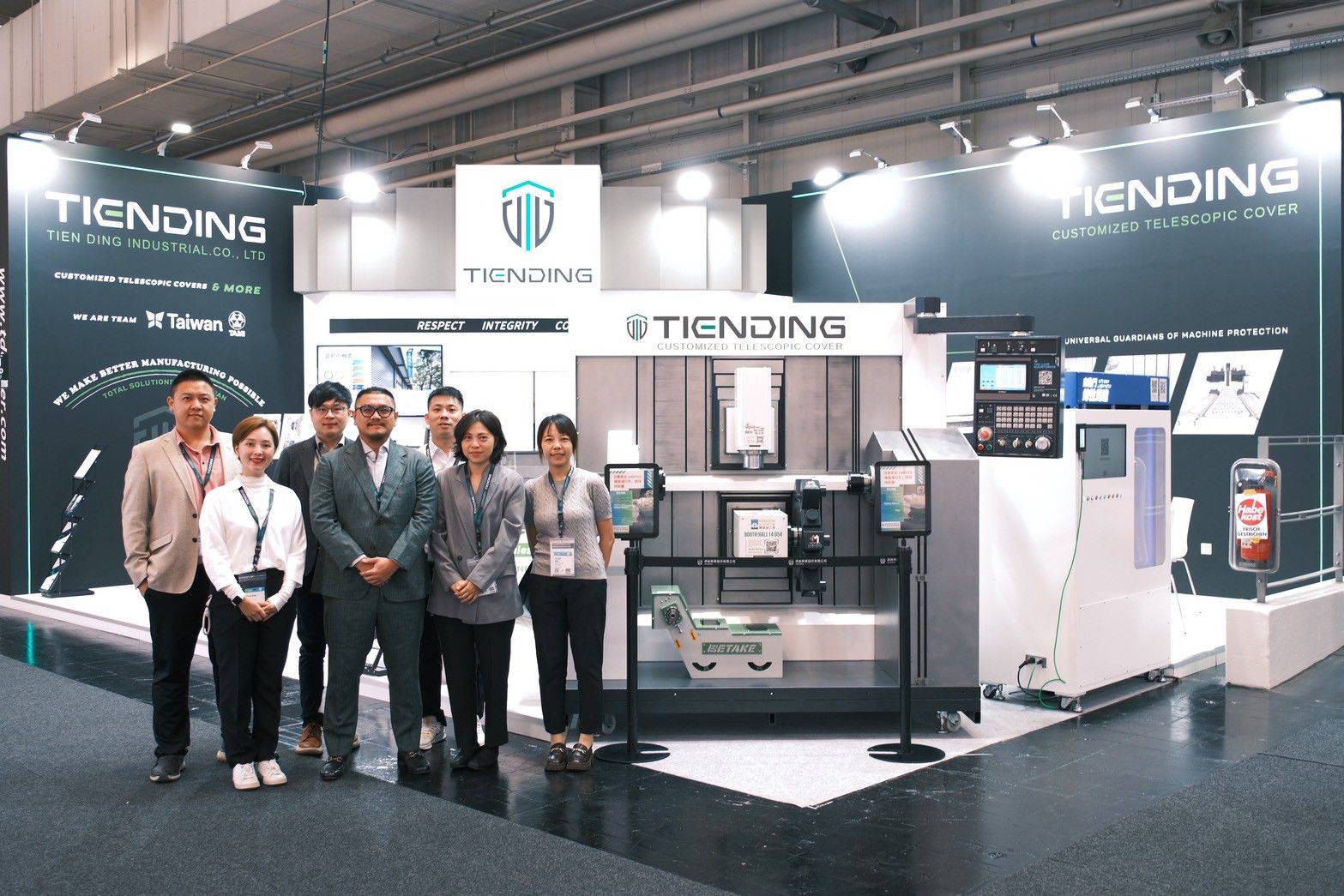

TIEN DING Debuts at EMO — Entering Germany’s Manufacturing Game-Changer with Highly Reliable Protective Cover Solutions

Exhibition and Global Manufacturing Trends

EMO, as an international barometer for machine tools and manufacturing technology, brings together key machinery manufacturers and buyers from Europe, Asia, and the Americas. Against the backdrop of supply chain restructuring, AI and automation upgrades, and accelerated EV manufacturing, machine protection (telescopic covers / guards) is no longer just an accessory but a critical component affecting production line stability, uptime, and overall costs.

Key Observations of the German Market

Social and Employment Perspective

Due to recent waves of Syrian and Ukrainian refugees, Germany has long provided subsidies, but with reductions expected, a new employment surge is anticipated. The manufacturing sector will become a key absorber of labor, driving demand for automation equipment, durable machinery, and highly reliable components.

Competitive Landscape

Chinese manufacturing has advantages in price and rapid product iteration, but still lags in after-sales service and customization capabilities. Many German companies bear extra costs due to inconvenient maintenance or insufficient customization, making the market increasingly favor suppliers with high reliability, customizability, and comprehensive service systems.

Future Drivers

- Automation and AI will continue to expand, with digitalization and efficiency improvement as core themes.

- After-sales service and system integration capabilities will become the competitive core, rather than purely price-based advantages.

- Emerging markets in Eastern Europe, India, and Turkey are rapidly rising and warrant continued investment.

TIEN DING’s Highlights at EMO

- Protective Covers for Large Machining Centers: Suitable for gantry five-axis machines, wind turbine blade processing, and mold machining.

- High-Speed Telescopic Covers: Supporting 5-axis turning-milling centers and high-speed machining centers, ensuring smooth extension and wear resistance.

- Custom Integration Capability: Using 3D modeling (e.g., PTC Creo) and engineering simulation to design covers tailored to customer machine specifications.

- High-Reliability Sliding and Guiding Technology: Reduces wear, lowers noise, improves stability, and directly decreases production line maintenance costs.

Strategies for the German and Global Markets

1. Strengthen European Collaboration and Local Services

Plan to establish closer partnerships with German and European OEMs while gradually implementing localized service points to meet high standards for after-sales and maintenance in the German market.

2. Support Automation and AI-Friendly Protection

Continue developing modular covers, standardized replaceable parts, and medium- to long-term smart maintenance knowledge bases to make covers more suitable for unmanned factories and intelligent production lines.

3. Expand in Emerging Markets

Actively invest in fast-growing markets such as Eastern Europe, India, and Turkey, leveraging Taiwan’s flexible supply chain and rapid delivery capabilities to accelerate market penetration.

Conclusion

EMO is not only a platform to showcase technology but also a lens to observe industry trends. Through this exhibition, TIEN DING demonstrates our technical strength and service capabilities: with high-quality telescopic covers and comprehensive customization support, we help global manufacturers improve uptime and machine reliability.

Learn More / Visit TIEN DING Official WebsiteCatagory

Recent News

Tien Ding Industrial Partners with Taiwan Suppliers to Shine at EMO Hannover 2025—with an Exhibition Concept Machine Built for Integration

Tien Ding Joins Taiwan-Japan Exchange and Prepares to Showcase Advanced Machine Covers at EMO Hannover 2025